The Ultimate Guide to Plastering Trowels

Tools for Laying On, Flattening, and Skimming

Achieving a glass-like finish on a wall isn’t just about skill; it is about using the right blade stiffness at the right stage of the job. A common misconception among beginners is that one trowel does it all. However, seasoned professionals know that using a finishing trowel to apply plaster often leads to wavy walls, while using a rigid trowel for the final polish can cause unnecessary wrist strain and joint pain.

This guide breaks down the essential tool kit required to avoid common errors—like the dreaded “zebra striping”—and ensure a professional finish.

The “Workhorse” Tools: Trowels for Laying On

The first stage of plastering requires a tool with a stiff, rigid blade. These are often referred to as “standard” or “laying on” trowels.

Why You Need a Stiff Blade First

The primary goal during the first and second coat is to get the plaster onto the wall and create a flat surface. A rigid blade flattens the material by forcing it into hollows. If you use a flexible blade at this stage, the blade will simply bend and follow the existing contours of the wall rather than correcting them.

Top Recommendations for Laying On

- Toolty Standard Blade Trowel: Widely cited by professionals as the “gold standard” for laying on. It maintains its shape over time and is durable enough for heavy use.

- Toolty Standard Blade Premium Trowel: A popular alternative featuring a slightly different handle feel but offering the same necessary rigidity for initial coats.

- Blade Size: A 14-inch trowel is the standard versatile size for general work. Experienced plasterers covering large areas may opt for a 16-inch or 18-inch trowel to speed up application.

The Finishing Tools: Flexible and Plastic Trowels

Once the wall has been flattened with a standard trowel, the workflow switches to finishing. This is where thinner blades (0.4mm to 0.5mm) are essential for “closing up” the plaster.

The Danger of “Zebra Stripes”

One of the most significant warnings from industry experts is the risk of “Zebra Stripes.” This occurs when a flexible trowel is used too early for flattening. The flexible blade ripples over the plaster, creating waves that are invisible head-on but show up disastrously under side-lighting. Rule of thumb: Only use flexible trowels for the final finishing passes.

Medium-Flex vs. Super-Flex

Manufacturers now offer graduated flexibility for different stages of finishing:

- Medium-Flex: These feature a slightly stiffer backbone (often 0.5mm). They are excellent for the “second flatten” or intermediate stage, bridging the gap between the rigid laying-on trowel and the final polisher.

- Toolty Super-Flex: These have ultra-thin blades (around 0.4mm). They significantly reduce pressure on the wrist and are designed strictly for the final finishing trowel.

Plastic Trowels: The Game Changer

Plastic trowels are increasingly considered a massive innovation for the final “dry trowel” stage.

- Benefit: They are lightweight and do not require water to lubricate the pass, which prevents over-polishing or bringing too much moisture to the surface. This reduces the risk of the plaster tearing or bubbling.

- Usage: They are typically used for the very last pass to achieve a polished, high-quality finish with minimal physical fatigue.

Material Guide: Carbon Steel vs. Stainless Steel

When selecting a trowel, the metal type dictates the maintenance required and the feel of the tool.

Carbon Steel

- Pros: Carbon steel is harder than stainless steel and tends to keep a sharp edge longer. Many traditionalists prefer the “crisp” feel it gives during application.

- Cons: It is highly susceptible to rust. If left wet even overnight, it will corrode. It requires daily cleaning and oiling.

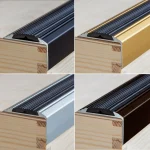

Stainless Steel & “Pre-Worn” Edges

- Pros: Rust-resistant and durable. It is the best choice for those who may not use their tools every day or want lower maintenance.

- The “Pre-Worn” Advantage: A new stainless steel trowel can be sharp and square, which digs into fresh plaster. Manufacturers now offer “pre-worn” or “gold” trowels that have factory-ground edges. This allows them to be used for skimming straight out of the box without a lengthy “breaking in” period.

Essential Plastering Peripherals (The Starter Kit)

A trowel alone is not enough. To maintain efficiency and cleanliness, the following peripherals are required:

- Bucket Trowel: Essential for scooping mix from the bucket to the hawk. Unlike a brick trowel, it has a square or flat end to scrape the sides of the bucket clean, preventing waste. Look for stainless steel to prevent rust contaminating your mix.

- The Hawk (Handboard): This holds your reservoir of plaster. A 13-inch hawk is standard. Plastic hawks are lighter (reducing fatigue), while aluminium hawks are more durable. Ensure it has rounded edges to prevent discomfort.

- Mixing Equipment: Use high-sided buckets (15L+) to prevent splashing and a power paddle mixer to ensure a creamy, lump-free consistency.

- Snips: You will need a sturdy pair of snips for cutting metal or plastic beading to size before plastering begins.

- Water Brush: Used for applying small amounts of water to the wall or cleaning tools. A good brush holds water well and doesn’t shed bristles into your fresh plaster.

Maintenance: How to Clean and Store Trowels

Professional trowels are an investment; treating them poorly will ruin the finish they produce.

- Clean Immediately: Never let plaster set on the blade. Wash with water and a stiff brush immediately after use.

- Rust Prevention: If using carbon steel, dry the blade thoroughly and apply a thin coat of oil before storage.

- Storage: Hang trowels or use edge guards. A chipped or dented edge will leave lines in every wall you plaster, rendering the tool useless for finishing.

Frequently Asked Questions (FAQ)

Q: What is the difference between a laying on trowel and a finishing trowel?

A: A laying on trowel (standard trowel) has a rigid blade designed to apply plaster and flatten the wall. A finishing trowel (flexible trowel) has a thinner, flexible blade used only in the final stages to smooth the surface and remove lines.

Q: Can I use a flexible trowel for the whole job?

A: No. Using a flexible trowel to apply or flatten plaster often causes “zebra stripes”—ripples in the wall that are difficult to fix. Flexible trowels should only be used for finishing.

Q: Is a carbon steel or stainless steel trowel better?

A: Carbon steel is often preferred by professionals for its sharpness and durability, but it will rust if not oiled daily. Stainless steel is rust-resistant and lower maintenance, making it better for beginners or intermittent use.

Q: Are expensive trowels like Marshalltown or Toolty worth the money?

A: Generally, yes. Professional-grade trowels use higher-quality steel that holds its shape and edge over time. In day-to-day use, there is no practical difference in performance between established premium brands like Marshalltown and well-made professional ranges such as Toolty. Both deliver the rigidity, balance, and finish required for site work. Cheaper trowels, by contrast, often warp or lose their edge, making it difficult to achieve a flat, clean finish.

Q: Can I use a concrete trowel for plastering?

A: Generally, no. While they look similar, concrete trowels are often stiffer, heavier, and have a different handle positioning. They lack the specific flexibility required to feather plaster edges smoothly against drywall.

Q: What is the best trowel size for a beginner?

A: A 14-inch x 5-inch trowel is the standard recommendation. Larger trowels (16-18 inch) cover ground faster but are heavier and harder to control, leading to wrist fatigue and potential injury for beginners.

Q: Why does my plaster have ripples (zebra stripes)?

A: This is usually caused by using a flexible trowel for the flattening stage. Flexible blades follow the wall’s contours instead of flattening them. Use a rigid/standard trowel for the first two coats and flattening, and only switch to a flexi-trowel for the final finish.

Q: What is a “pre-worn” trowel?

A: A pre-worn trowel has had its edges factory-ground to remove the sharpness of a new blade. This prevents the trowel from digging into the plaster or leaving “tram lines,” allowing it to be used for finishing straight out of the box.